Scandic Built Radiant began nearly 15 years ago when we, through our custom home building business, Scandic Builders Inc., identified the opportunity to solve the challenges and limitations of traditional radiant heating systems. Throughout the years, we experimented with various iterations of radiant solutions, continuing to improve both the efficiency of the installation process as well as the operational effectiveness of the system once it is up and running.

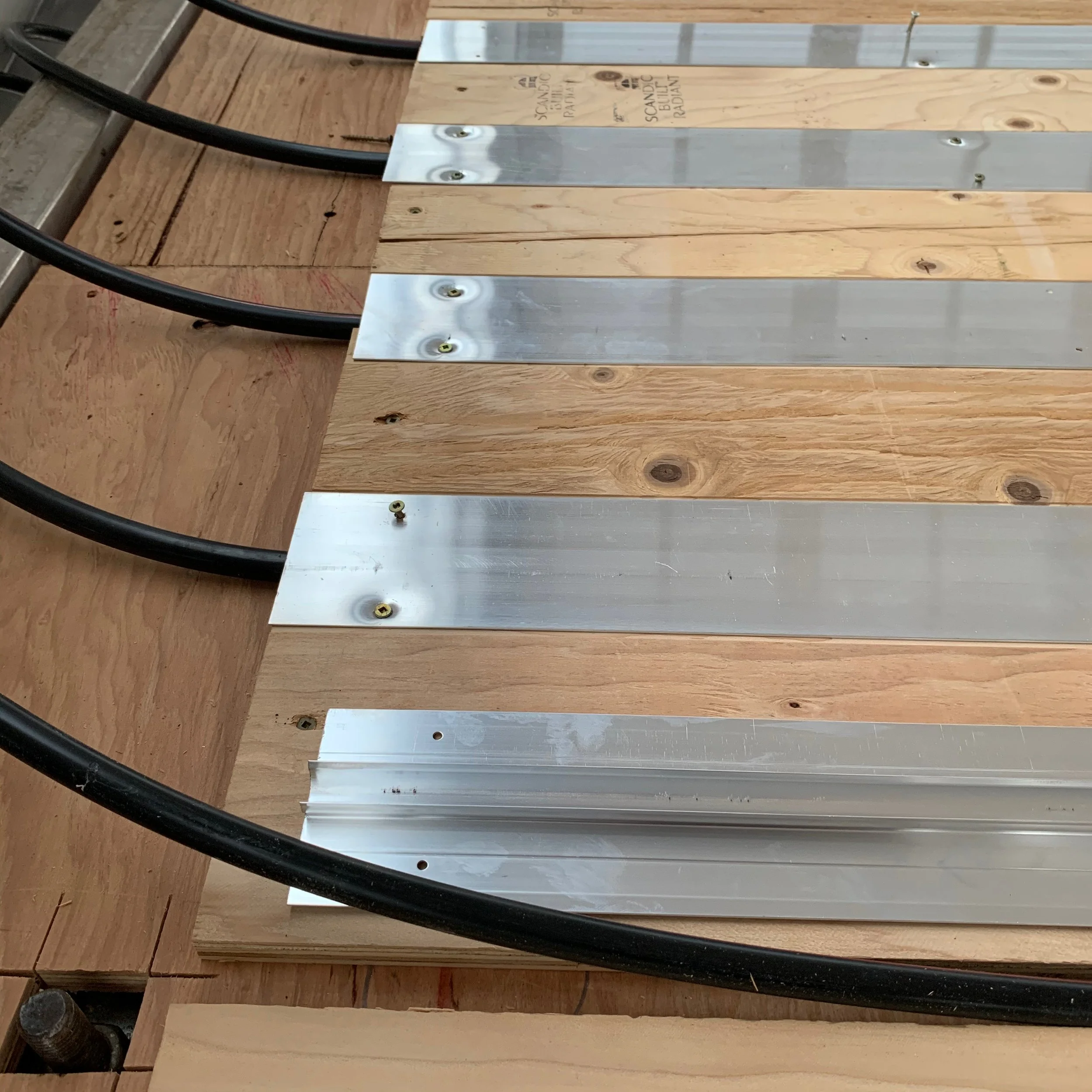

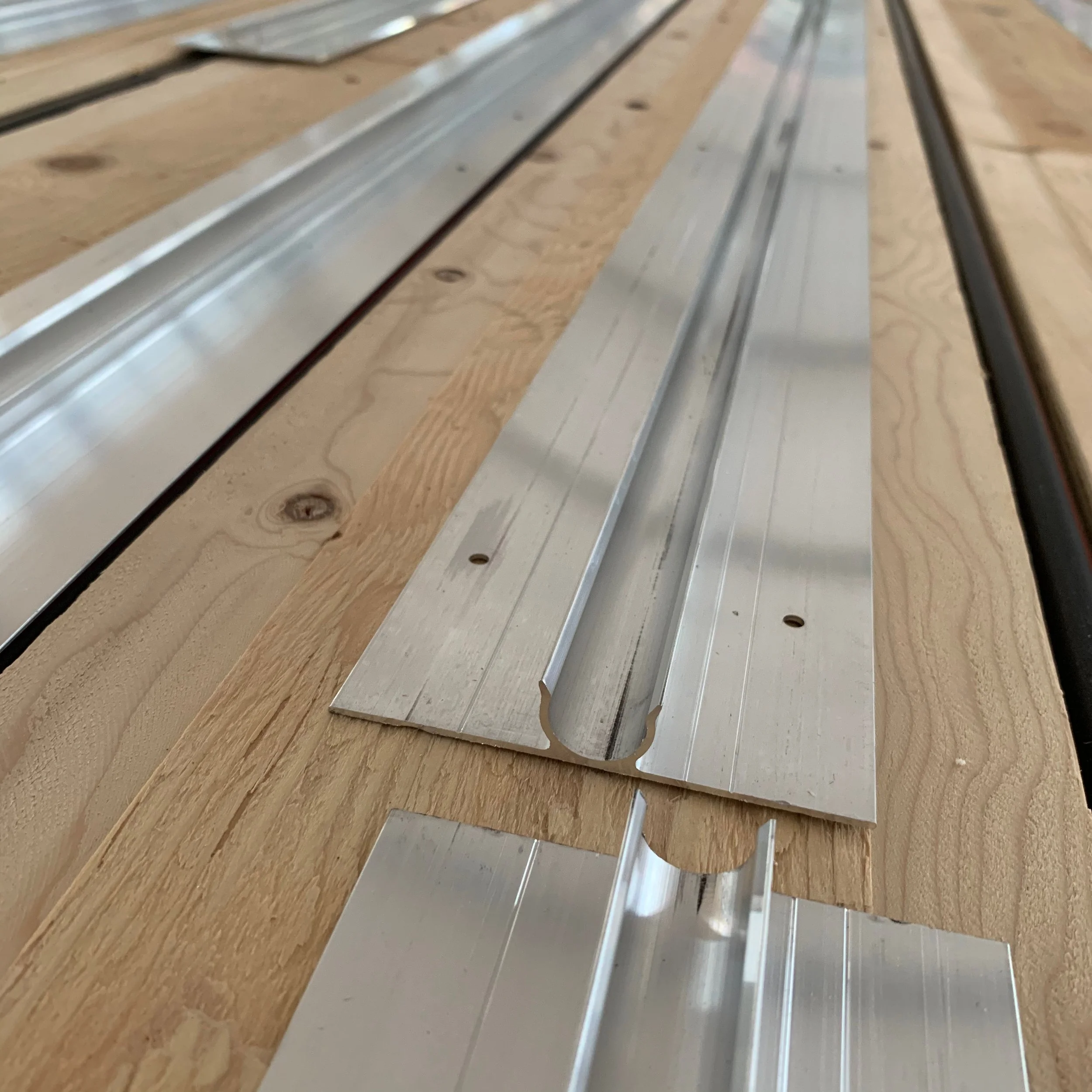

This resulted in the development of a radiant system consisting of a thick heat transfer plate, which covers and encases the tubing, in both the straight runs as well as the U-bends, ensuring that all parts of the tubing are protected.

Our current system received Patent No. US 10,006,643 BI in June 2018. The system in its current form has been installed in 5 large, custom homes; approximately 30,000 sq ft to date.

In our system, the radiant tubing is covered by a thick heat transfer plate, which covers and encases the tubing preventing any punctures from heavy foot traffic, accidental drops or punctures from screws or nails. In addition, that same heat transfer plate also serves a second purpose, conducting the heat and dispersing it to a larger surface area, increasing its energy-efficiency.

We partnered with an excellent local millwork to create custom designed components, and with a Canadian provider who is able to deliver plywood within the extremely low tolerances we require for a flush, seamless solution. A local metal work machine shop fabricates both the aluminum U-bends as well as the straight run pieces based upon our specifications.

Overall, our system provides for increased energy efficiency with increased protection and lower installation costs.

There are several environmental benefits to our system. First, the heating surface is considerably larger than in other systems, so a lower water temperature is required to achieve the same level of heat transfer, providing for increased operational energy-efficiency.

This provides an improved room climate with healthier humidity levels. As in other radiant systems, this method decreases the circulation of air inside the room, minimizing the spread of unhealthy, airborne particles.

Unlike the competitors, in our system the radiant tubing is covered by a thick heat transfer plate, protecting the tubing and preventing any punctures during the remainder of the construction project, as well as during the installation of the flooring. This eliminates the need for additional, temporary layers to protect the system, saving time, money and resources, and allows for the finished flooring to be installed at the end of the project, protecting that investment.